Titanium etching

Titanium metal plate is a metal plate made of titanium as a raw material. Titanium is a very special metal. It is very light in texture, but it is very tough and corrosion-resistant. It will not turn black like silver, and it will maintain itself at room temperature for life. 's hue. The melting point of titanium is similar to that of platinum, so it is often used in aerospace. Military precision parts.

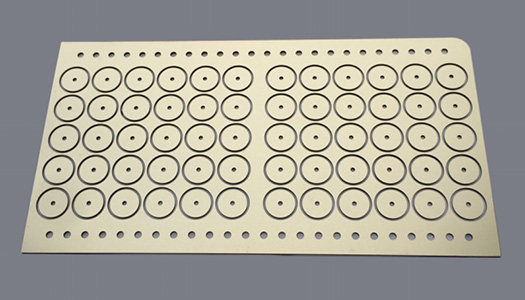

Titanium etching is a subtractive metalworking process that uses specialized etchants to delineate intricate, high-precision precision parts.

The titanium etching process involves the use of specialized etchants to dissolve the metal to delineate intricate, high-precision precision parts. Chemical etching allows rapid prototyping to high-volume titanium parts without leaving stress or burrs on the metal.

The chemical etching process allows half-etching on metal surfaces and is ideal for secondary methods of forming shielded components and connectors. Another advantage of the etch process is cost-effective repeatability of parts, such as wire meshes containing many holes or irregular shapes. Compared to other processes, the cost of machining one hole is the same as that of machining a million holes, and the manufacturing speed is fast and burr-free.

Titanium Etched Parts

Craniomaxillofacial implants

Dental membranes

Heat exchangers

Current collector grids

Hearing aid membranes

Materials

Commercially pure (grades 1-4)

Alloyed (grades 5-38)

Full material stock list