What is stainless steel etching

Stainless steel etching is a machining process that uses chemical etchants to create complex and precise components from sheet stainless steel. It is a highly accurate and repeatable process with no mechanical burr or stress placed on the material.

Suitable steel and stainless steel grades

Etched stainless steel is a steel with rust and corrosion resistance as its main characteristics, and a chromium content of at least 10.5% and a carbon content of not more than 1.2%. Chromium produces surface oxides when exposed to oxygen, making it stronger and more resistant to corrosion. In addition, cold rolled stainless steel further increases the strength and gives it a smooth shiny finish. Stainless steel is popular in many types of industrial components.

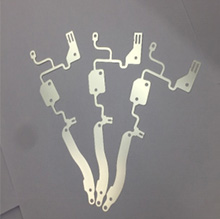

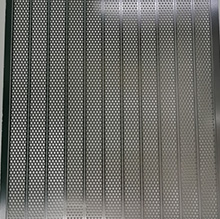

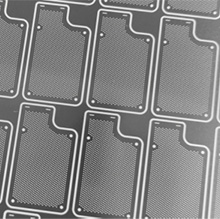

Surface Preservation - Part surfaces remain smooth while part features are etched with high precision and low tolerances. Maintaining a smooth, scratch-free surface is especially ideal for parts such as nameplates, speaker grills, and other types of features.

High Strength - The strength of stainless steel increases with the addition of nickel and cold working. Aerospace and vehicle components will be able to withstand forces and resist structural fatigue.

Ductility and Formability - Nickel-containing stainless steel grades are also easier to bend; ideal for contacts and board-level shielding.

Excellent corrosion resistance, high temperature and low temperature - stainless steel itself has good corrosion resistance, and stainless steel can still maintain its excellent physical and mechanical properties at high temperatures. This is an essential feature for high performance of machines and components exposed to temperature changes.

Recyclable - At the end of the product life cycle, stainless steel components can be recycled to help reduce costs.

| Low carbon (mild) steel | All grades |

| Electrical steel | Transil |

| Maraging steel | All grades |

| Sandvik strip steel | 20C,Chromflex (7C27Mo2, 13C26, 12C27, 6C27), Hiflex |

| Uddeholmstrip flapper valve steel | 716,UDDEHOLM UHB 20C |

| High carbon (spring) steel | All grades |

| Stainless steel | Austenitic (300 series), ferritic/martensitic (400 series), precipitation hardened (17-4, 17-7), duplex, super duplex |

Advantages of stainless steel etching

Prototype to production - fast

Low cost fast design, unlimited complexity - fast

Burr-free and stress-free - metal properties are not affected

Delivery times are measured in days, not months - fast

Suitable for all steel grades

Accuracy is ±0.02mm