Plate heat exchangers

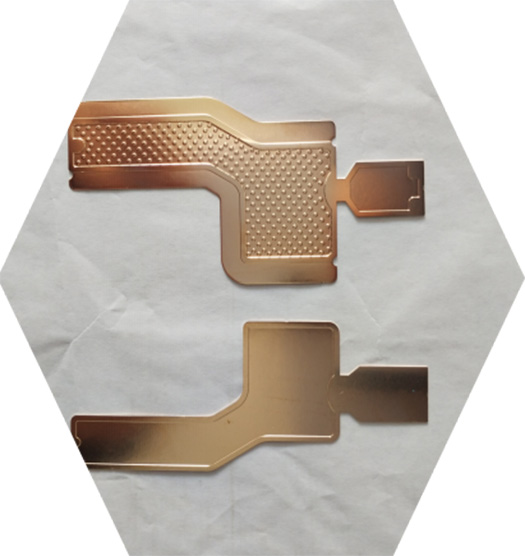

ZYH etching manufactures plate heat exchangers,printed circuit heat exchangers (PCHE) flow plates,heat transfer plates,cooling plates for mobile phones, communication electronics, hardware equipment, automotive systems, new energy batteries and natural gas production.

| Material Selection: | C5191 or other custom materials |

| Thickness Range: | 0.1mm,0.12mm,0.15mm,0.2mm,0.25mm |

| Typical Applications: | Microchannel heat exchangers Diffusion bonded heat exchangers Compact heat exchangers Cooling plates Heat transfer plates Vapor chambers Plate heat exchangers printed circuit heat exchanger (PCHE) |

| Plate Heat Exchangers Features: | The lines of the etching processing precision hardware products are uniform and free of burrs. Reduce heat exchanger area, volume and weight while improving heat transfer efficiency to volume ratio. |

Advantages of etching

Low development cost -

Any modification can be made according to the designer's requirements. Half-etching of metal surfaces can also be achieved. Whether it is one hole or a million holes, or a very complex shape, the cost remains the same.

Fast delivery -

It only takes 3 to 10 working days from model confirmation to mass production. If the shipment is particularly urgent, we will do our best to help.

High precision -

Chemical etching can create complex metal parts - high precision etching down to ±0.020mm.

Burr-free, stress-free, smooth -

Chemical etching produces no mechanical or thermal stress, unlike CNC machining, stamping and laser machining, which can affect flatness and subsequent assembly.

Materials

Steel and stainless steels

Aluminium

Copper and copper alloys

Nickel and nickel alloys

Titanium

Full material stock list