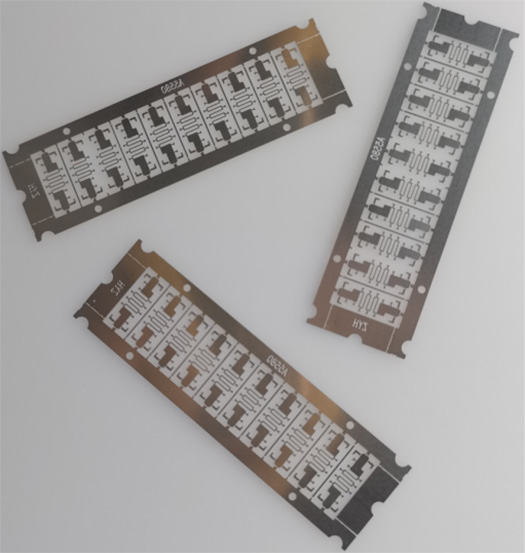

Heating wire/ electric heating wire

Heating wire, also called resistance wire or electric heating wire, called heating film in the automotive industry, is a component that generates heat after being connected to electricity to achieve a certain purpose.

Material selection: Commonly used metal materials are: copper, iron-chromium-aluminum, nickel-chromium alloy, pure nickel, titanium, 316L stainless steel, etc.

Applications: Heating wire or electric heating wire, mainly used for charging car batteries and electronic cigarette vaporizer/electronic cigarette core.

Advantages of etching

Low development cost -

Any modification can be made according to the designer's requirements. Half-etching of metal surfaces can also be achieved. Whether it is one hole or a million holes, or a very complex shape, the cost remains the same.

Fast delivery -

It only takes 3 to 10 working days from model confirmation to mass production. If the shipment is particularly urgent, we will do our best to help.

High precision -

Chemical etching can create complex metal parts - high precision etching down to ±0.020mm.

Burr-free, stress-free, smooth -

Chemical etching produces no mechanical or thermal stress, unlike CNC machining, stamping and laser machining, which can affect flatness and subsequent assembly.

Materials

Steel and stainless steels

Aluminium and aluminium alloys

Titanium and titanium alloys

Copper and copper alloys

Nickel and nickel alloys

Full material stock list