Nickel etching

Nickel is a hard, ductile and ferromagnetic metal that is highly polished and resistant to corrosion. Heavy non-ferrous metal materials based on nickel and other alloying elements. In order to further improve the physical and chemical properties of nickel and meet the requirements of scientific technology and industrial development, it is necessary to add an appropriate amount of alloying elements to nickel. Nickel alloys are mainly used in electronic, chemical, mechanical, medical, energy development and marine, aviation and aerospace sectors.

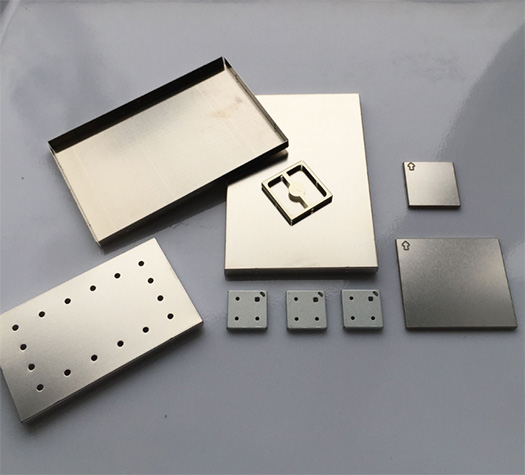

Our nickel etching services provide fast, burr-free, distortion-free nickel-based components in any nickel grade.

Unlike stamping, chemical etching uses low-cost digital tools to offset expensive stamping tools. This means prototypes and production parts can be available in as little as a few hours, rather than weeks or months.

Advantages of Nickel etching

Prototype to production - fast

Low cost fast design, unlimited complexity - fast

Burr-free and stress-free - metal properties are not affected

Delivery times are measured in days, not months - fast

Suitable for all Nickel grades

Accuracy is ±0.015mm

Nickel Etched Parts

EMI/RFI shielding

Connectors and contacts

Shims, gaskets and washers

Heat sinks

Bipolar fuel cell plates