Energy

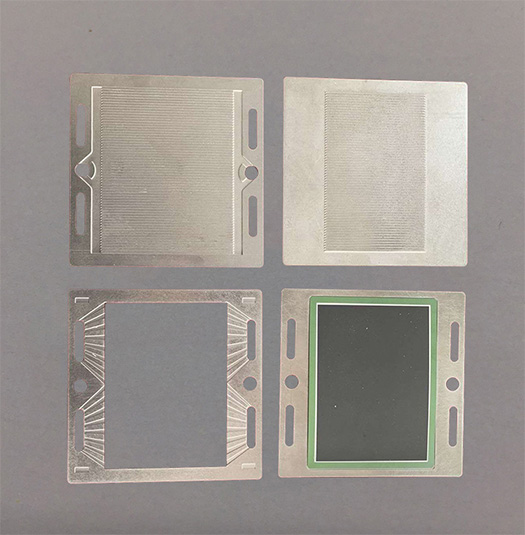

Through cooperation with the world's leading new energy suppliers, our etching process is used for fuel cell bipolar plate etching processing.

Product function: separate fuel and oxidant to prevent gas permeation. Collect and conduct current, with high conductivity. The designed and processed flow channel can evenly distribute the gas to the reaction layer of the electrode for electrode reaction. It can discharge heat and keep the battery temperature field uniform.

Product features: high etching efficiency, uniform lines and high precision.

With more than 10 years of etching experience and partnership with reliable suppliers, the ZYH team is committed to producing high-quality, high-demand etched parts, and has established long-term cooperative relationships with domestic and foreign customers, and we look forward to establishing more partners relation.

Whether the number of parts is large or small, the size of the part is small or large, we can meet the challenge. We can usually produce prototypes within 24 hours.

Advantages of Photo Etching

The metal bipolar plate is easy to process, can be manufactured in batches, has low cost, thin thickness, and has high volume specific power and specific energy of the battery.

Materials

Steel and stainless steels

Aluminium

Copper and copper alloys

Nickel and nickel alloys

Titanium

Full material stock list

Precision parts produced for Energy

Fuel cell plates

Heater elements

Heat exchangers

Meshes, filters and sieves

Lead Frames

Contacts

Connectors

Gaskets