Electronic

With the advancement of technology, electronics are more accessible than ever. Rising demand for electronics drives the market to produce cheaper quality products and components. At the same time, higher requirements are put forward for the miniaturization, light weight and convenient carrying of electronic products. Chemically etched parts for the electronics industry must adhere to the highest quality, high precision, and tiny volume.

The photochemical etching process allows half-etching on metal surfaces and is ideal for secondary methods of forming shielded components and connectors. Another advantage of the etch process is cost-effective repeatability of parts, such as wire meshes containing many holes or irregular shapes. Compared to other processes, the cost of machining one hole is the same as that of machining a million holes, and the manufacturing speed is fast and burr-free.

As one of the largest photochemical etching manufacturers in China,with more than 10 years of etching experience and partnership with reliable suppliers, the ZYH team is committed to producing high-quality, high-demand etched parts, and has established long-term cooperative relationships with domestic and foreign customers, and we look forward to establishing more partners relation.

Our fully automatic roll-to-roll integrated etching line (integrating etching, stripping, cleaning, drying, and polishing) can produce 3,000 square meters per day, which can meet a large number of rapid delivery needs.

Whether the number of parts is large or small, the size of the part is small or large, we can meet the challenge. We can usually produce prototypes within 24 hours.

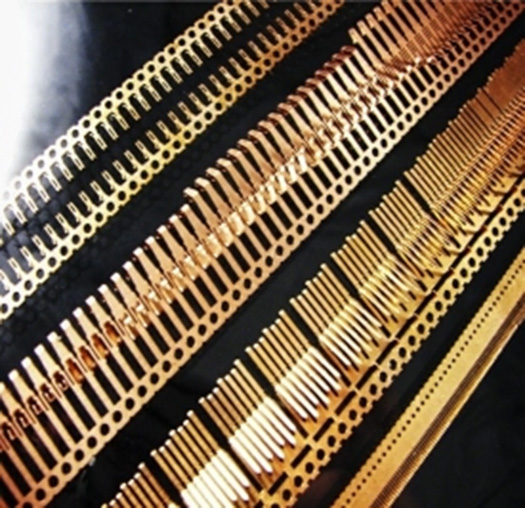

Precision parts produced for Electronics

Lead Frames

Bus Bars

Step Lids

Flat Springs

Contacts

Connectors

Gaskets

Filters

Shims

Encoder Disks

Semiconductor Cooling Plates

Board Level Shielding (BLS)

EMI/RFI Shielding Components

Materials

Steel and stainless steels

Aluminium

Copper and copper alloys

Nickel and nickel alloys

Titanium

Full material stock list

Advantages of Photo Etching

Prototype to production - fast

Low cost fast design, unlimited complexity - fast

Burr-free and stress-free - metal properties are not affected

Delivery times are measured in days, not months - fast

Suitable for all steel grades

Accuracy is ±0.015mm