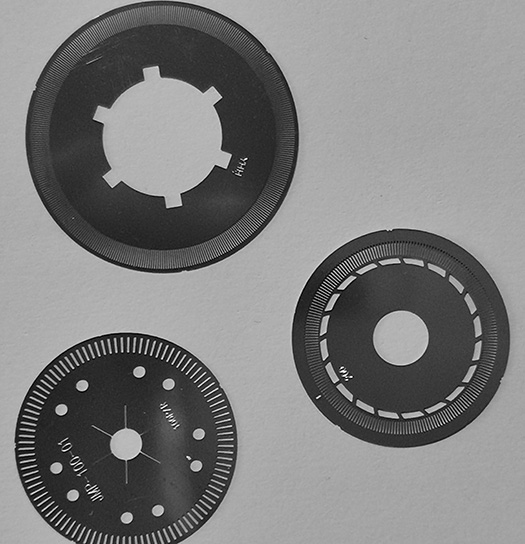

Encoder Disk

Generally speaking, the code wheel is the grating disc of the photoelectric encoder.

Etched encoder disk has the advantages of strong resolution, high measurement accuracy and reliable operation, and is one of the most commonly used displacement sensors for measuring the position of shaft rotation angle.

Etched metal code discs are generally made of stainless steel 304, with a thickness of 0.03-0.3. The strip-shaped holes of the code disc produced by ZYH etching factory have precise dimensions and can meet customer requirements.

Advantages of etching

Low development cost -

Any modification can be made according to the designer's requirements. Half-etching of metal surfaces can also be achieved. Whether it is one hole or a million holes, or a very complex shape, the cost remains the same.

Fast delivery -

It only takes 3 to 10 working days from model confirmation to mass production. If the shipment is particularly urgent, we will do our best to help.

High precision -

Chemical etching can create complex metal parts - high precision etching down to ±0.020mm.

Burr-free, stress-free, smooth -

Chemical etching produces no mechanical or thermal stress, unlike CNC machining, stamping and laser machining, which can affect flatness and subsequent assembly.

Materials

Steel and stainless steels

Aluminium and aluminium alloys

Titanium and titanium alloys

Copper and copper alloys

Nickel and nickel alloys

Full material stock list