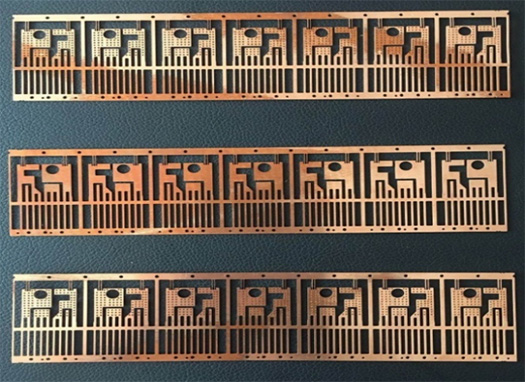

Copper etching

Photo chemical etched copper components are used in electronic systems in many industries. Because copper has excellent electrical and thermal conductivity, copper material etching parts will improve the ability to handle high voltages and currents.

Since our inception, we have been etching copper components for well-known electronics companies. Copper is softer than other metals, easy to etch, and provides precise results. Although it is highly corrosion resistant, finishing the copper parts with a nickel flash base plate and/or adding a silver plate overlay will further improve its corrosion resistance. Additionally, adding tinplate to etched components will increase high temperature tolerance and improve solderability.

Copper alloys, such as phosphor bronze, beryllium copper, brass, and nickel silver, have most of copper's functional properties, but adding elements can also improve strength, conductivity, and corrosion resistance.

The following list of copper and copper alloy properties will help you choose the right metal for your project. With copper etching experience in our factory, we can help you choose the most functional and cost-effective type for you.

Copper properties

Electrical conductivity - excellent thermal and electrical conductivity

Corrosion resistant - even more so with nickel and silver baseplates

Ductility - easy to bend if an overmolding operation is required

Non-magnetic - helps protect against EMI emissions

Solderable - can be soldered without adding plating

Extensibility - can be flattened or stretched

Benefits of Copper Chemical Etching

Since copper is a softer metal, some sheet metal fabrication processes can compromise the structure of the part. For example, stamping during stamping can lead to deformation, especially with small and/or perhaps porous. Photochemical etching excels in precision and maintaining low dimensional tolerances without burrs and distortion.

Chemical etching has proven to be the most precise and cost-effective method for smaller and thinner parts popular in microelectronics and RF microwave products. Simultaneous fabrication methods are fast, and pickling leaves parts surfaces and edges clean and smooth.

The advantages of photochemical etching of copper compared to other types of metal fabrication processes are as follows:

Low-cost complex designs - When high volume production is required, copper parts with small holes, slits, slots or other complex features cost less than other manufacturing processes.

Low-Cost Tooling - Tooling is produced quickly and at a fraction of the cost of traditional hard tooling. Prototype modifications are inexpensive.

Burr-Free and Stress-Free—Parts are etched evenly and quickly, eliminating the need for a single point of contact.

Metal properties remain the same - copper properties remain the same as there is no heat affected zone

Materials

Beryllium copper

Brass

Copper

Ferry

Nickel silver

Phosphor bronze

Copper Etched Electronics Parts

lead frames

connectors

flat springs

EMI/RFI shielding

busbars

step lids

contacts

meshes

screens

antennas

pins

RF waveguides

shims

gaskets