Automotive

We understand that the automotive industry is constantly challenged to meet changing market demands and highly regarded safety standards. ZYH provides automotive chemical etching services with high quality, high precision and fast delivery chemically etched parts to help meet these challenges.

The chemical etching process is repeatable, so small holes, complex, and unique designs can be produced quickly. Whether it’s one hole or a million holes, regardless of shape, the manufactured part remains burr-free, deformation-free, and costs the same.

The ZYH half-etch capability enables fuel cell plates with unique fluid flow and heat exchange design channels.

Chemically etched stainless steel is the best material choice for fuel cells and other automotive components because of its corrosion resistance and excellent thermal and electrical conductivity.

As the consumer market for electric vehicles changes, automotive batteries and other engine systems require more efficient heat transfer components, so the demand for aluminum etching products is gradually increasing. Aluminium etched products can also meet the requirements of light vehicles due to their high strength to low weight ratio.

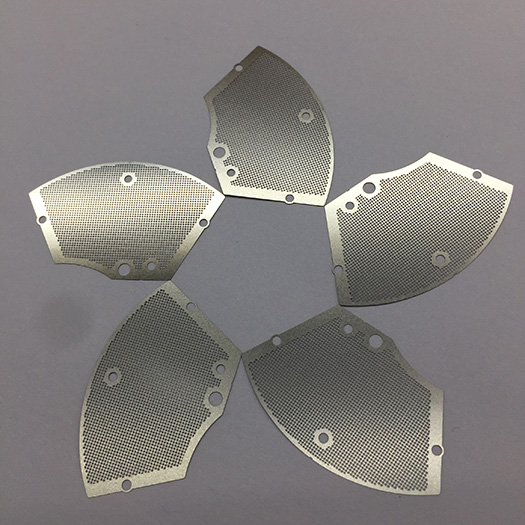

Precision parts produced for Automotive

Damper Shims

Electronic Connectors

Heat Exchanger Plates

Oil Control Valve Filter

Lead & Covers

Name/Logo Tags

Speaker Grills

Fuel Cell Frames

Fuel Cell Screens

Fuel Cell End Caps

Encoder Disks

Flat Springs

Spacer Washers

Filters for Fuel Injectors

Materials

Steel and stainless steels

Aluminium

Copper and copper alloys

Nickel and nickel alloys

Titanium

Full material stock list

Advantages of Photo Etching

Prototype to production - fast

Low cost fast design, unlimited complexity - fast

Burr-free and stress-free - metal properties are not affected

Delivery times are measured in days, not months - fast

Suitable for all steel grades

Accuracy is ±0.015mm