Aerospace

We know the aerospace and military industries have the highest quality and safety standards and can withstand extreme temperature changes. ZYH chemical etching is available on all aerospace metal grades, including aluminum and titanium. These metal materials are often difficult to form using traditional sheet metal processing. If the traditional sheet metal process will leave burrs and stress, it is easy to deform. And our etching process can make parts free of burrs and deformation, without changing material properties and stress, while maintaining safety.

As one of the largest photochemical etching manufacturers in China, with over 10 years of etching expertise, etching experience and partnership with reliable suppliers, the ZYH team is committed to producing high-quality and demanding etched parts, and has established long-term cooperative relationships with domestic and foreign customers, and we look forward to building more many partnerships.

According to the product type, after the customer provides the parts drawings, we can deliver the goods within 8 hours at the earliest.

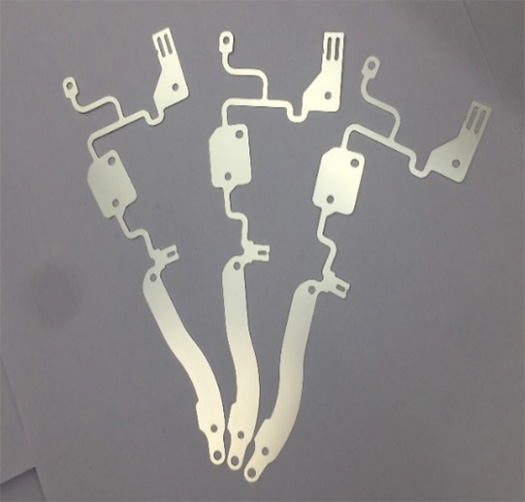

Precision parts produced for aerospace

Air intake grilles and filters

Precision Metal Gaskets and Washers

Lead frames

Dashboard and Cabin Trim Parts

flat spring

EMI/RFI shielding cans and assemblies

Plate heat exchangers

Materials

Steel and stainless steels

Aluminium

Copper and copper alloys

Nickel and nickel alloys

Titanium

Full material stock list

Advantages of etching

Prototype to production - fast

Low cost fast design, unlimited complexity - fast

Burr-free and stress-free - metal properties are not affected

Delivery times are measured in days, not months - fast

Suitable for all steel grades

Accuracy is ±0.015mm